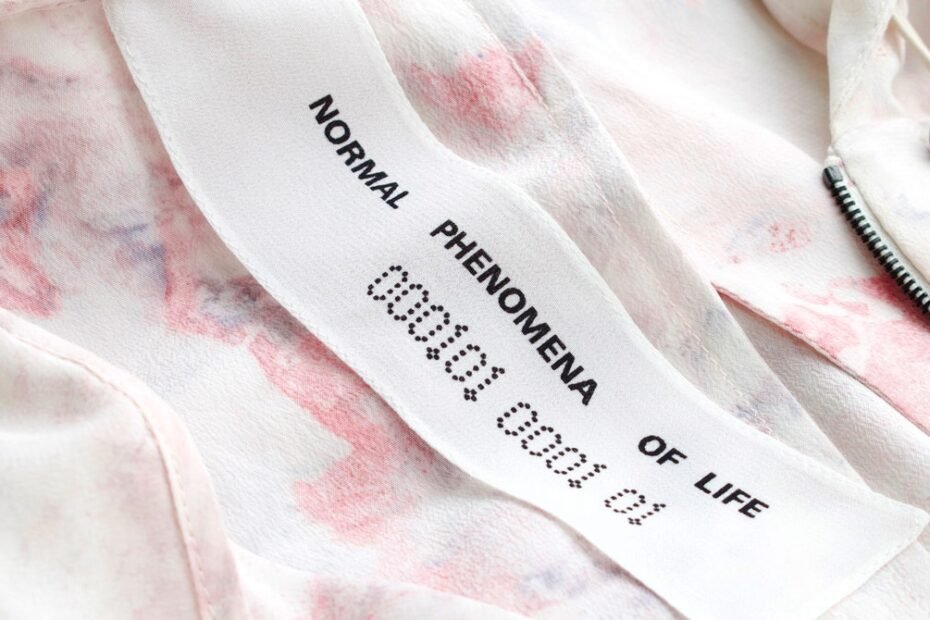

The Exploring Jacket isn’t your regular anorak. Its color comes not from dyes, but from a pigment-producing bacteria called Streptomyces coelicolor. When applied directly to a fabric and left to incubate, the bacteria cells produce a compound in a spectrum ranging from reds and pinks to blues and purples—in eye-catching patterns that evoke the grain of polished marble.

This jacket is just one of the unusual products for sale on Normal Phenomena of Life (NPOL), an online platform launched in 2023 by Natsai Audrey Chieza, the founder of London-based R&D studio Faber Futures, and Christina Agapakis, the creative director of Boston-based biotech company Ginkgo Bioworks. Their goal? To harness the power of living organisms to develop materials and objects. This is biodesign.

“Nature has evolved over billions of years to assemble atoms in much smarter and more efficient ways than human beings have been able to achieve. And so, as we look to decarbonize and divest from fossil fuels, it turns out that nature has solutions that biotechnology is enabling us to leverage,” says Chieza, who has a degree in architecture but became fascinated by biodesign when pursuing a master’s degree in material futures at Central Saint Martins in London.

By tapping into naturally occurring living systems, many of the products in NPOL’s catalog have a lower carbon footprint than their everyday counterparts. For instance, the bacterial dye used to create the Exploring Jacket uses significantly less water than conventional plant-based dyes, as no farmland is needed.

NPOL’s latest product is the Gathering Lamp, which is made from bioconcrete. Grown at ambient temperatures using limestone-producing bacteria, bioconcrete has 95 percent fewer emissions than traditional cement—which is typically manufactured by burning limestone—and is three times as strong. Plus, the Gathering Lamp is designed to be easily repaired, upgraded, or recycled at the end of its useful life. “We’re looking at keeping materials in circulation. After all, we can’t be investing billions of dollars into building new biobased materials, only for them to end up in landfill,” Chieza explains.